1: Osnove valovite škatle

2: Slogi valovite škatle

3: Vrste valovitega kartona

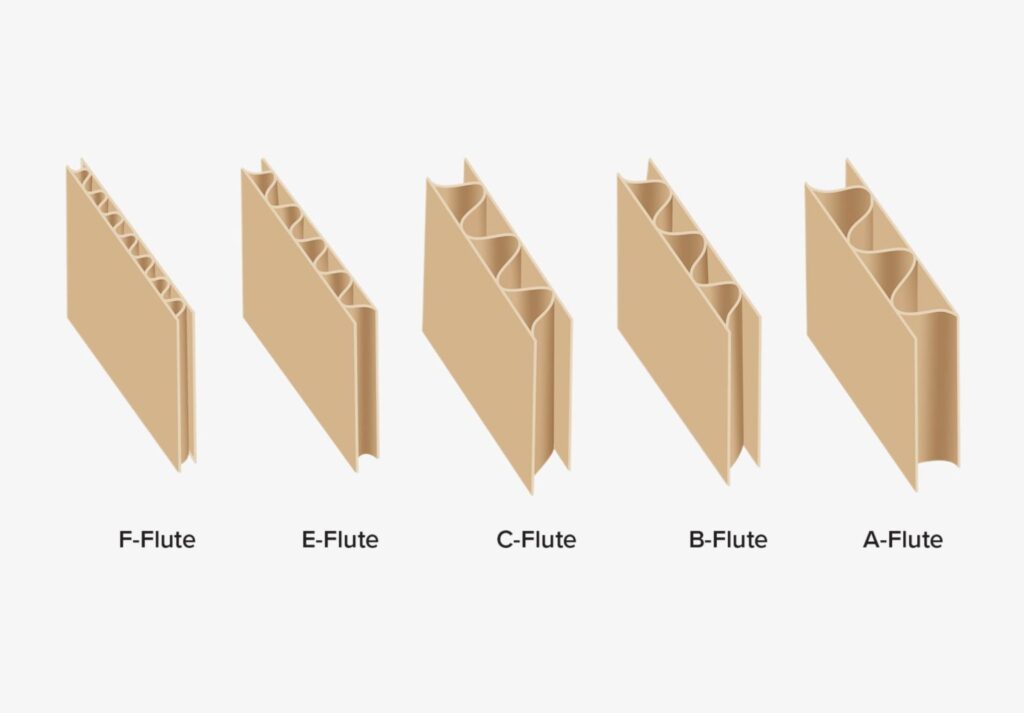

Valoviti karton je na voljo v različnih vrstah, kot so enostranski, enostenski, dvostenski in trostenski, pri čemer vsaka ponuja različne stopnje zaščite. Izbira je odvisna od teže izdelka in potrebne ravni zaščite.

Valovita flavta je podobna oblogam, razen konstrukcije.

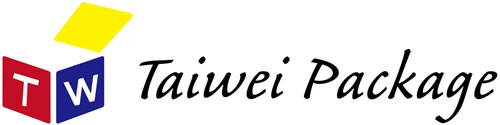

Valovita folija zagotavlja vaši embalaži blaženje, trdnost in odpornost proti stiskanju, odvisno od različnih razredov, kar omogoča še večjo prilagoditev embalaže. Preden pa podrobneje preučimo vsak razred folije, si oglejte našo tabelo valovitih folij za hitro vizualno primerjavo:

A-flavta – 1/4” je prva vrsta valovitega kartona. Ta vrsta kartona ima najvišje zaščitne in blažilne lastnosti. Zelo dobro prenaša stiskanje in zlaganje ter se pogosto uporablja za pakiranje krhkih predmetov.

A-flavta – 1/4” je prva vrsta valovitega kartona. Ta vrsta kartona ima najvišje zaščitne in blažilne lastnosti. Zelo dobro prenaša stiskanje in zlaganje ter se pogosto uporablja za pakiranje krhkih predmetov.

B-flavta – 1/8”. Ta flavta je videti veliko tanjša od drugih, vendar je še vedno precej močna, z odlično odpornostjo na prebadanje in drobljenje. B-flauta ima izjemno vsestransko zmogljivost za različno embalažo ali kot dodaten material za oblazinjenje in razdeljevanje. Ima celo bolj ravno površino za kakovostnejši tisk in enostavno izrezovanje.

C-flavta – 3/16” je fleksibilen in eden najbolj vsestranskih tipov valovitega kartona za zvitke. Ima povprečno odpornost proti drobljenju, trdnost pri zlaganju in tiskarske lastnosti. Verjetno ste že videli, da se C-Flute uporablja za ladijske škatle, pa tudi za pakiranje stekla, mlečnih izdelkov in pohištva.

E-flavta – 1/16” se običajno ne uporablja za pošiljanje. Debelina E-flusa je na tanjši strani razredov z flusami, zato se pogosto uporablja kot alternativa za zložljive kartonske škatle. Vendar pa lahko E-flus še vedno uporabite za kozmetiko, krhko steklo, keramiko in druge majhne in občutljive izdelke. E-flus ima odlično tlačno trdnost, odpornost proti drobljenju in relativno ravno površino za visokokakovostno tiskanje.

F-flavta – 1/32” ima zaščitne lastnosti, podobne kot E-Flute, vendar s še bolj gladko površino za visokokakovosten tisk. V ameriški industriji hitre prehrane se F-Flute običajno uporablja za školjkasto embalažo, v Evropi pa je ta vrsta valovitega papirja standardna možnost za specializirano in maloprodajno embalažo.

4. Debelina valovitega kartona

Zdaj, ko smo obravnavali različne vrste papirnatih podlog in razredov za flavte, je čas, da si ogledamo debelino! Spodaj je povzetek standardnih možnosti debeline, ki so na voljo:

Obloga – »Obraz« plošče iz vlaknenih plošč. Na to ploščo prilepite flavto.

Enojni obraz – Sestavljen je iz ene obloge z nalepljenim žlebom, vidnim na eni strani.

Enojna stena – Najpogostejša debelina. Dve oblogi z vmes prilepljeno žlebljeno vlakneno ploščo.

Dvojna stena – Trije listi obloge in dve vmesni plošči z žlebljenimi vlakni.

Trojna stena – Štirje listi obloge in tri vmesne plošče z žlebljenimi vlakni. Ta možnost lahko prenese težjo težo do skoraj 136 kg, vendar je manj fleksibilna.

Če si nekoliko bolj natančno ogledamo dvojne in trojne stene, so pri teh možnostih možne različne kombinacije vrst utorov. Nekatere industrijske standardne kombinacije vključujejo:

Flavta AC – Mešanica dveh najbolj zaščitnih vrst valovitega kartona. AC Flute je odlična, če potrebujete dodatno zaščito pri zahtevnih postopkih pošiljanja in ravnanja.

flavta BC – Ta kombinacija, ki je izjemna v vseh pogledih, zagotavlja visoko stopnjo zaščite med prevozom in je običajna za transportne škatle.

EB flavta – Zagotavlja vrhunsko trdnost in varnost pri prehodu, medtem ko zunanji E-flute omogoča odlično, visokokakovostno površino za tiskanje.